SMW Refrigeration and Heating recently finished work on a property in north Phoenix. This was a pretty complicated project and involved completely rebuilding the entire HVAC system in the home.

Pictured Above. Outside of home when project started.

Expanding The Home, Insulating It And Determining Tonnage

Insulation Specifications

[table]

Part Of The Home, Insulation

Walls (Existing), 4″ Brick and 4″ Block and Spray Foamed With 2″ Fired Out On North Side For Electrical

Walls (New), 2″x6″ Wood Frame With 6″ Of Spray Foam In Attic

Attic, Encapsulated With 6″ Of Spray Foam

Windows, Dual Pane Simonton SHGC 0.23/Value 0.29

Foundation, Existing Concrete Slab [/table]

Zoned XV20i AC System & Accessories For The Project Install

- The 4-ton system was divided into two zones using Trane’s Comfortlink zoning system. The master bedroom suite was placed on its own zone, and the rest of the west side was placed on the other zone.

- The 3-ton System was designed to cool the expanded great room and the kitchen area but was not zoned.

Both systems were connected to an R-8 flex duct system that was sized according to ACCA Manual D procedures. Installed into the supply plenums of each unit was Activtek Induct 2000 UV lights to help clean and disinfect the air in the home. SMW also installed super quiet 80 cfm Delta Breeze Greenbuilder exhaust fans in all the bathrooms and laundry room, and a special Panasonic 110cfm Whisper Warm Fan with a built-in 1400 watt heater in the master bath. The roof venting for the dryer and rangehood were also provided by us.

Air Conditioning Equipment

The table below outlines all the air conditioning equipment chosen

[table]

Part, Equipment Model

Condensing Unit, 4 Ton and 3 Ton Trane XV20i Heatpump

Air Handlers, Trane TAM8 Hyperion

Thermostat, XL950 with Comfortlink II Zoning

Air Cleaner, Activetek Induct 2000

Ductwork, R-8 Flex

Grilles, Bar Type Return OBD Supply

Exhaust Fans, Panasonic Whisperwarm/Delta Breeze Greenbuilder [/table]

XV20i AC condenser pictured above

Pictured Above. Duct work being installed.

Stages Of Installing The Equipment

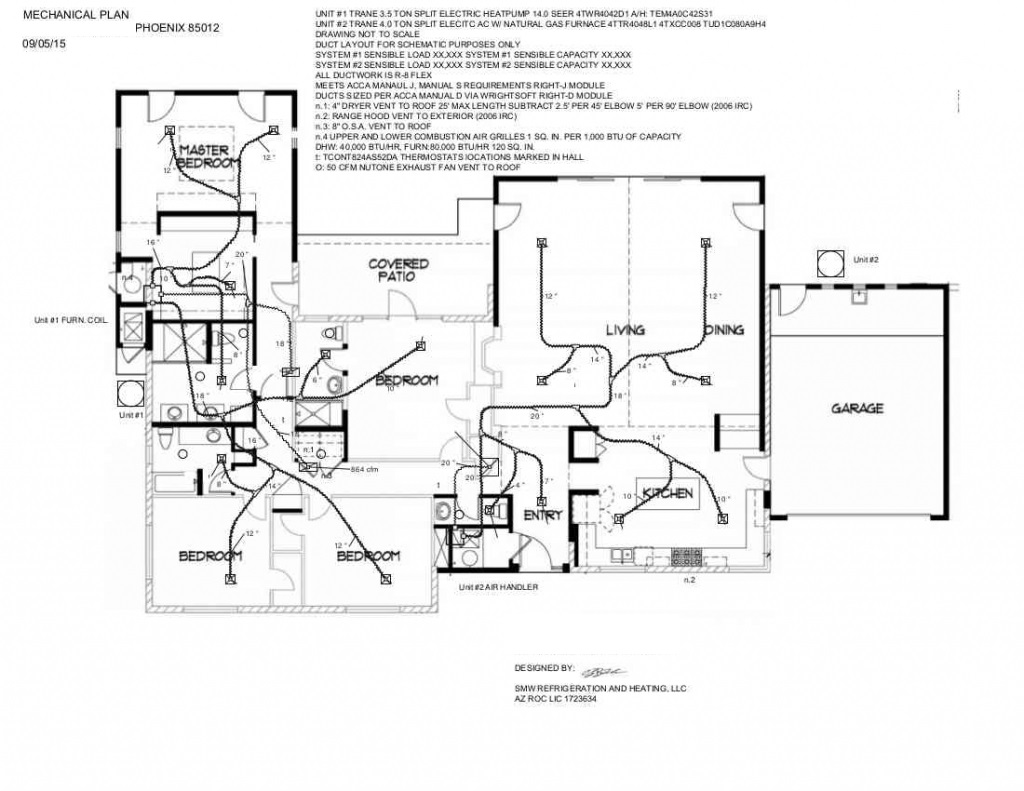

Mechanical Plans were drawn up then submitted to the city of Phoenix for a building permit, meanwhile, SMW waited for the call to start the work and made plans to do the installation in 3 Stages.

- First, the air handlers, linesets, ductwork, register cans, and exhaust fans were installed in the home.

- The second stage consisted of installing the condensing units, and all the grills for the ductwork and filters.

- Lastly, the thermostats were done, the new AC units were fired up for the first time, and the refrigerant charge was set.

However, once the install was complete two more things needed to be done.

- SMW completed an air balance on the home, testing the airflow to each room to make sure that the air conditioner met all the values from the load calculation.

- Finally, blower door testing was performed on the home, to test the air tightness of the home and ductwork.

Starting with patient planning and then getting proper permission from the city, we successfully installed the new AC units and saw that they performed to desired specifications.

March 2017 Update

Below is the customer’s electrical usage since the installation was done.

[table]

Bill Date, Billing Days, Total Usage (kWh), Average (kWh)

2/24/17, 28, 543, 19,

1/27/17, 29, 616, 21

12/29/16, 30, 606, 20

11/29/16, 33, 573, 17

10/28/16, 29, 784, 27

9/28/16, 30, 1067, 36

8/29/16, 32, 1453, 45

7/28/16, 30, 1416, 47

6/28/16, 32, 1352, 42

5/27/16, 29, 803, 28[/table]