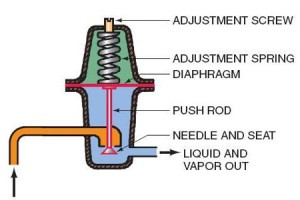

The thermostat expansion valve is a modulating valve that opens and closes in order to feed the proper amount of refrigerant to the evaporator. Unlike the capillary tube, which does not modulate fluid flow, and the automatic expansion valve, which is designed to maintain a constant pressure in the evaporator, the thermostatic expansion valve is designed to maintain a constant evaporator superheat. The device modulates so that it can change for external conditions to regulate the flow of refrigerant. The thermostatic expansion valve operates on a “seat and needle” concept that is very similar to the automatic expansion valve. The main difference is that the TXV closes as the system load is reduced while the AEV closes as the system load is increased.

To understand how the thermostatic expansion valve operates, it’s important to understand how evaporator superheat is measured. Superheat is the amount of sensible heat (sensible heat is just measurable heat) that is added to the refrigerant after it has boiled off into a vapor. Superheat is calculated by subtracting the evaporator saturation temperature from the evaporator outlet temperature.

Refrigerant entering the compressor needs to be 100% vapor to prevent component damage. The thermostatic expansion valve ensures that this happens. The amount of superheat that will be maintained by the valve depends on the setting of the superheat spring and the size of the valve.

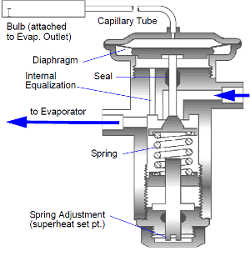

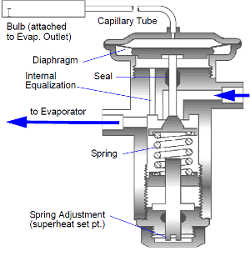

The thermostatic expansion valve’s “needle and seat” is controlled by three pressures that position the needle properly to feed the correct amount of refrigerant to the evaporator. The pressures push on a diaphragm, which is a thin and very flexible piece of steel, whose position determines the position of the needle in the seat. The three pressures are:

*Evaporator pressure

*Spring Pressure

*Bulb Pressure

Evaporator Pressure

The evaporator pressure is one of the pressures that helps close the valve. It attempts to push the needle into the seat to reduce the flow of refrigerant in to the evaporator. The evaporator pressure can be taken from either the inlet or the outlet of the coil. If the pressures drop (difference from the inlet and outlet pressure) across the evaporator coil is small, the inlet and outlet pressures are relatively close to each other. A Thermostatic expansion valve that senses pressure at the inlet of the evaporator is called an internally equalized valve; a thermostat expansion valve that senses the evaporator outlet pressure is called an externally equalized valve.

Spring Pressure

The spring pressure, also known as the superheat spring pressure, determines how much superheat the evaporator will open with. The higher the spring pressure, the higher the amount of superheat. The spring comes factory set and should only be adjusted by trained professionals, because improperly adjusted superheat springs can cause major system damage, including compressor failure. The spring pressure is the other pressure that closes the valve, reducing the amount of refrigerant flowing into the evaporator.

The evaporator pressure and the spring pressure both deliver the closing pressure for the valve.

Bulb Pressure

The bulb pressure is the only pressure that opens the valve. This pressure is generated inside a thermal bulb that is mounted at the outlet of the evaporator. The line that connects the thermal bulb to the thermostatic expansion valve is called the transmission line. The thermal bulb is refrigerant filled and for the most part follows a pressure/temperature relationship. It is the thermal bulb that senses the evaporator outlet temperature. The refrigerant in the thermal bulb is isolated from that of the system so no mixing takes place. The refrigerant in the bulb exerts a specific amount of pressure depending on its temperature that pushes down on the diaphragm, opposing the evaporator and spring pressures.